1. Electric Powder Coating Oven Overview and Components

An Electric Powder Coating Oven uses electric heating elements to cure powder-coated surfaces on metal objects. Core components include a thermally insulated chamber, electric coils or infrared panels, digital temperature controllers, airflow fans, and adjustable racks. These ovens are praised for precise temperature control, making them ideal for detailed or heat-sensitive projects.

Electric Powder Coating Ovens are widely used in automotive repair (for motorcycle frames, car parts), furniture manufacturing (metal chairs, tables), and electronics (appliance housings). They are also popular in small workshops and laboratories due to their clean operation and suitability for indoor use.

Prices start at 3,000forcompactbenchtopmodelsandgoupto80,000 for large industrial systems. Mid-range batch ovens (for small businesses) cost 10,000–25,000. Infrared electric ovens, known for rapid heating, are 15–20% pricier than standard coil-based units.

Preheat the oven to 170–210°C, aligning with the powder manufacturer’s specifications. Place coated items on non-reactive racks, ensuring space between parts for airflow. Use a timer to avoid overcuring, and clean the chamber weekly to prevent powder residue buildup.

Evaluate workspace size, voltage requirements (220V or 380V), and production volume. Opt for ovens with programmable temperature profiles for multi-stage curing. Check for certifications like UL or CE and prioritize energy-efficient models with ceramic insulation.

Ensure proper grounding to prevent electrical hazards. Install ventilation systems to remove fumes and avoid circuit overloads by verifying power supply compatibility. Use heat-resistant gloves and never leave the oven unattended during operation.

Electric ovens reduce energy costs by 25% compared to gas models, thanks to precise heat management and minimal waste. Insulation upgrades (e.g., ceramic fiber) improve thermal retention, while modular designs allow scalability for growing operations.

Q How often should I maintain an electric powder coating oven?

A Inspect heating elements monthly and replace damaged coils promptly to ensure efficiency.

Q Can electric ovens cure metallic powders?

A Yes, precise temperature settings support specialty coatings like chrome or bronze finishes.

Q Are electric ovens eco-friendly?

A They produce no direct emissions, making them compliant with indoor air quality standards.

Q What size oven is best for automotive parts?

A Choose a chamber at least 20% larger than your largest item (e.g., car rims).

Q Do electric ovens work in cold environments?

A Insulated models maintain stable temperatures even in unheated workshops.

This guide highlights the advantages of electric powder coating ovens, from precision to sustainability. By selecting the right model and adhering to safety protocols, businesses can achieve durable, high-quality finishes while optimizing operational costs.

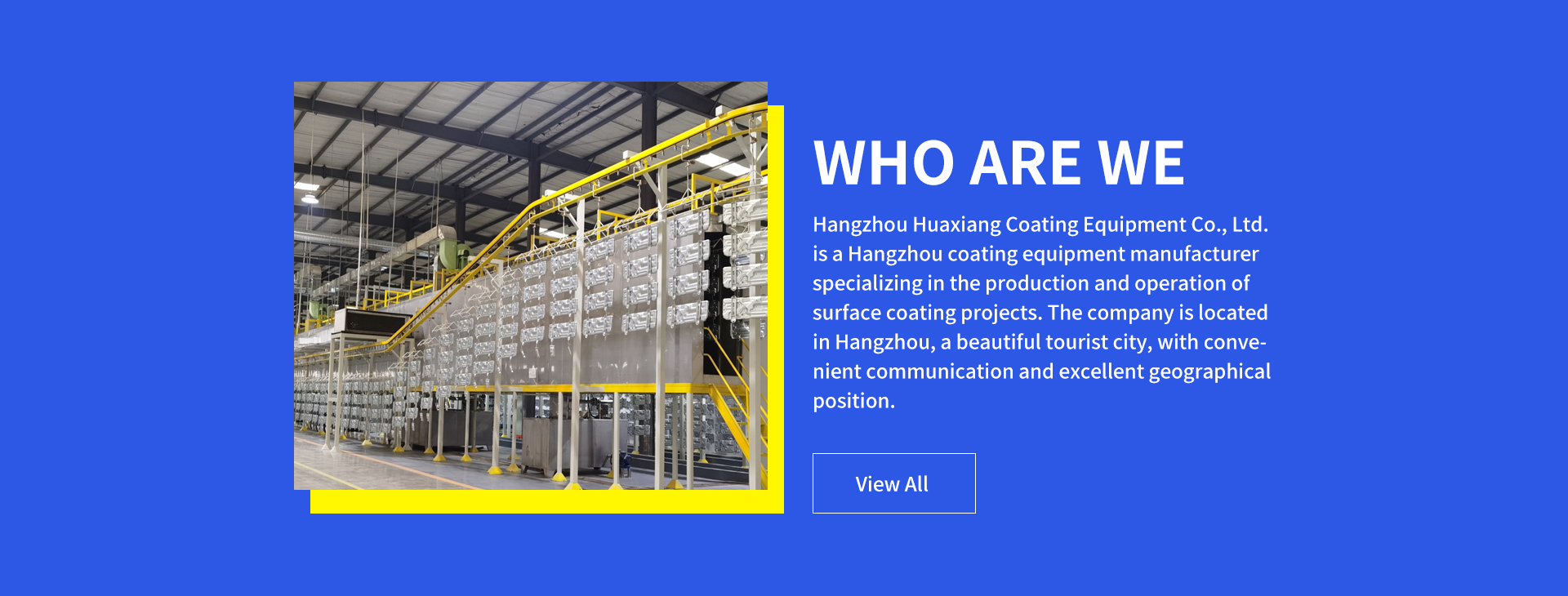

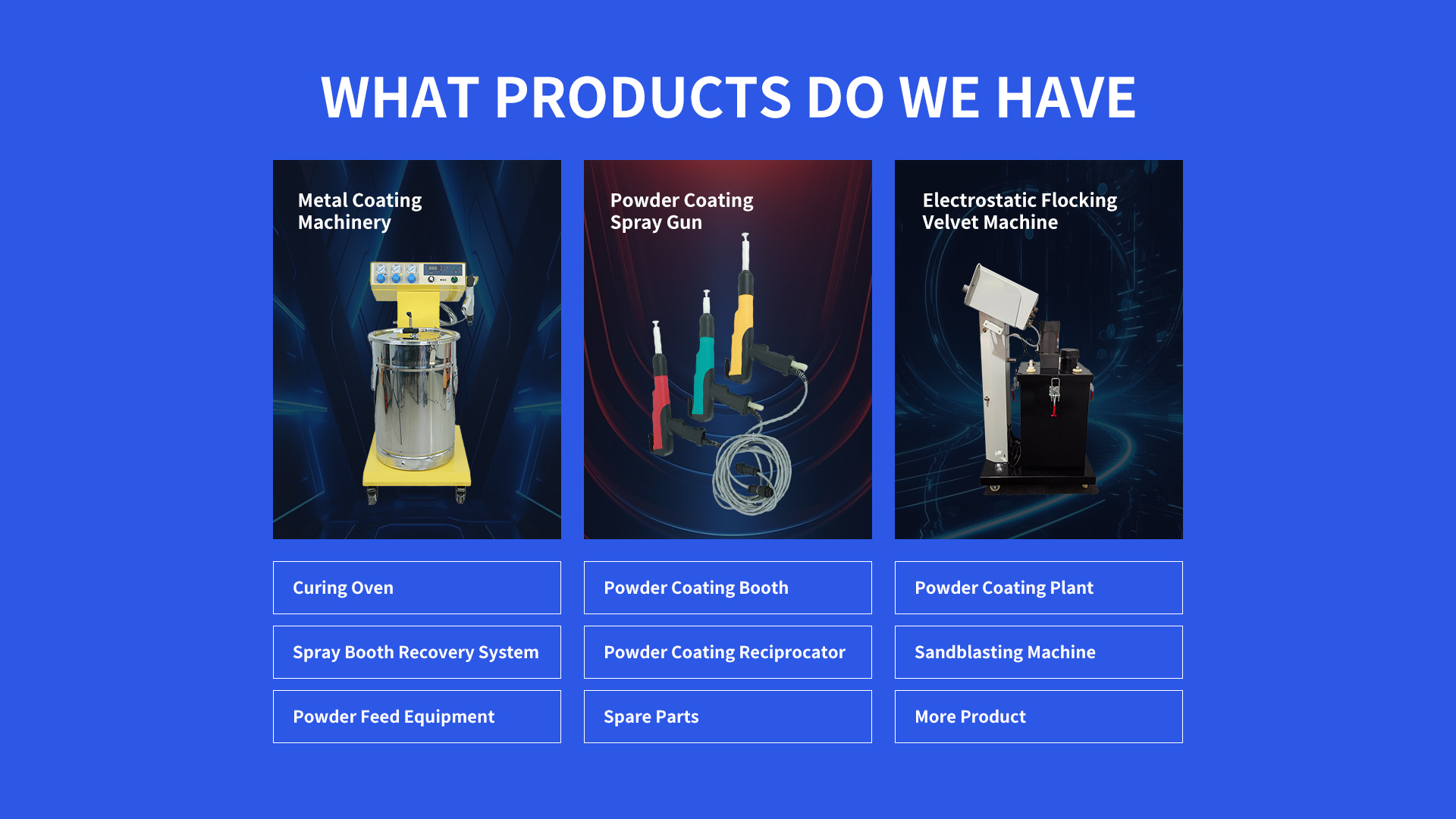

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com